THE RIGHT FORCE IN THE RIGHT PLACE

Sufficient blank holding force is of particular importance for sheet metal deep drawing operations. The hydraulic system is ideally suited for generating this holding force. The integration of one or more hydraulic functions in one tool, offers optimal solutions and high economic efficiency. Faster tool changes, the elimination of mechanical transmission elements and a much faster operational readiness, are just a few positive features. Hydraulic systems guarantee a high controllable blank holder force. This makes hydraulics in the tool extremely flexible and safe compared to other systems. Safe when holding the sheet to avoid wrinkles – safe in terms of economy.

ADVANTAGES

HYDRAULICS DIE CUSHIONS – AS INDIVIDUAL AS THE APPLICATION

We do not offer off-the-shelf solutions. Every product has its own story. We only proceed consistently the same in a few points:

In a well-thought-out design, in manufacturing accuracy and in absolute accuracy of fit in the tools.

FORMING HAS A NEW CHARACTER

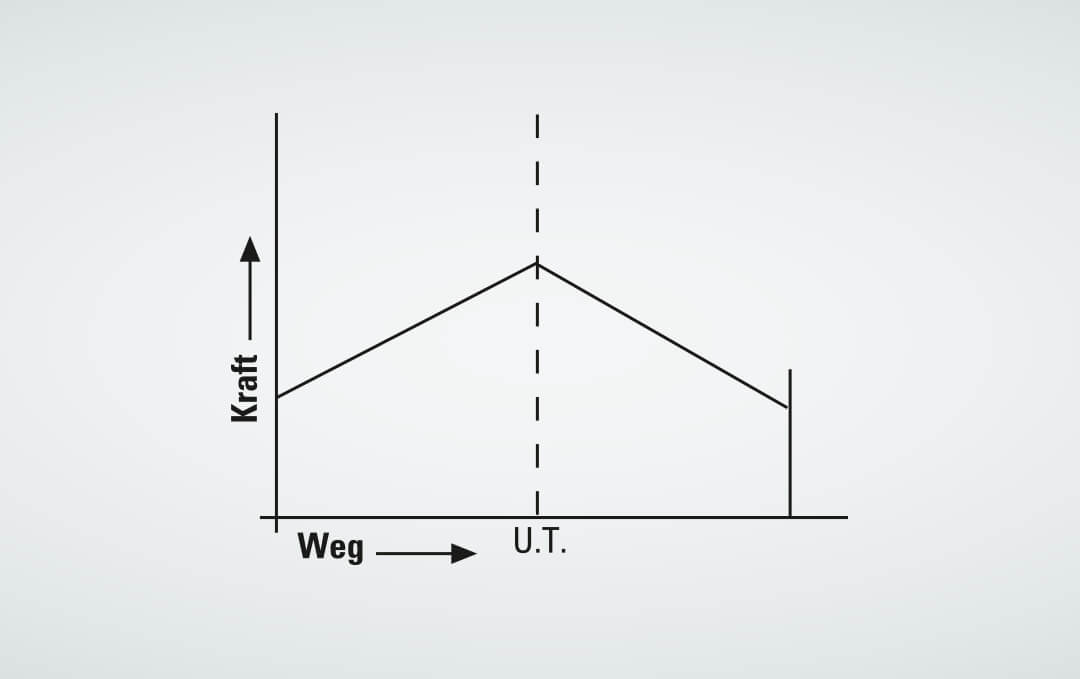

CHARACTERISTICS OF A SPRING

In single-acting presses, the blank holder force must be generated directly inside the tool. Conventional systems (e.g. gas springs, mechanical springs, air cushions) have narrow limits due to the relatively low blank holder force and unfavorable characteristics. The blank holder force achieved is relatively low, the increase in force, up to the end of the stroke, is extremely disadvantageous. The result: too little force for the formation, tears in the sheet, possibly damage to the press.

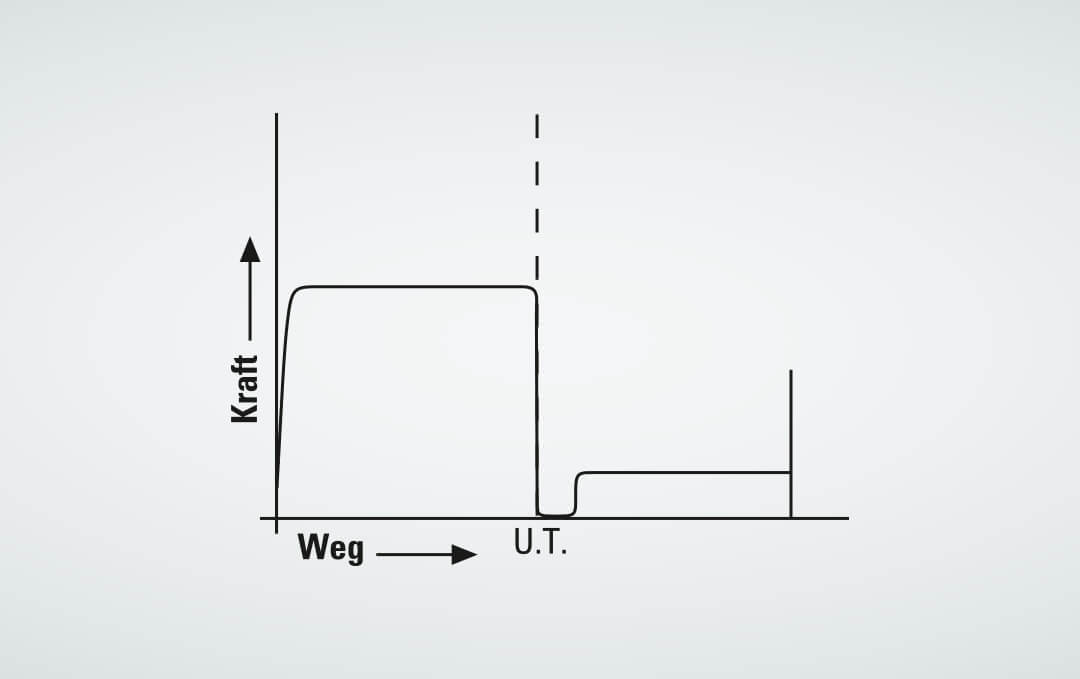

CHARACTERISTICS OF A HYDRAULIC BLANK HOLDER

Hydraulic blank holders offer a superior method. Very high force can be generated in the smallest space, enabling highest surface pressures until the sheet is held firmly. Advantage: Immediate force build-up, no material flow from the outside, no bracing of large parts, constant characteristics, progressive or degressive control options, pressure discharge in BDC of the press stroke, delayed return.